w3logistics feiert erfolgreichen LEAN-Projektabschluss

Die w3logistics AG beteiligt sich seit 2010 neben dem Kerngeschäft regelmäßig an Forschungsprojekten. In Zusammenarbeit mit der Universität Duisburg-Essen und weiteren Kooperationspartnern werden im Rahmen der Forschungsprojekte interessante Techniken in der Logistik erforscht, die in das Produktportfolio einfließen und unmittelbare Vorteile für die Kunden bieten.

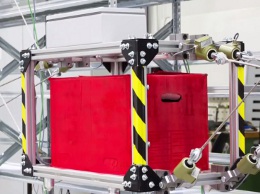

Das Forschungsprojekt „LEAN“ gehört zu einem der zehn, durch den Leitmarktwettbewerb MobilitätLogistik.NRW ausgewählten Beiträge, die zusammen mit rund 9,5 Mio. € EFRE-Mitteln und ungefähr 3,8 Mio. € Co-Finanzierung gefördert wurden und beschäftigte sich mit der Entwicklung von neuartigen Leichtbau-Regalbediengeräten auf Basis von Seilrobotertechnologie. Das Projekt mit einer Laufzeit von gut drei Jahren wurde als Kooperationsprojekt durchgeführt, bei dem Experten aus verschiedenen Branchen gemeinsam forschten. Neben der Universität Duisburg-Essen sowie weiteren Unternehmen, war auch die w3logistics AG beteiligt. Das Ziel des Projektes bestand darin, den gewonnenen technologischen Fortschritt in der Seilrobotik aus den Vorgängerprojekten in neue Produkte und Anwendungen für die Transport- und Logistikbranche umzusetzen.

Im Rahmen des Projektes fokussierte sich das Dortmunder Softwarehaus in erster Linie auf die informationstechnische Integration des Regalbediengerätes in die vorherrschende Systemlandschaft, sowie auf die Entwicklung mobiler Lösungen für die Bedienung des Geräts und des angebundenen Lagerverwaltungssystems. Die Flexibilität der eigenen Logistik-Suite w3/max unter Beweis zu stellen und das System weiterzuentwickeln, stellten für w3logistics wesentliche Aspekte bei der Beteiligung am Forschungsprojekt dar. Neben neuen Schnittstellen und Optimierungsstrategien, konnte ein technologischer Fortschritt im Rahmen des Ausbaus des eigenen Simulators und der Entwicklung einer Webapplikation erreicht werden. Mithilfe des Simulators konnte die Seilroboter-Anbindung simuliert und die zu realisierende LVS-App erfolgreich implementiert werden, die eine leistungsfähige Alternative zu bestehenden PC-Clients darstellt.

Die Ergebnisse des Forschungsprojektes bieten der w3logistics AG ein enormes Anwendungspotenzial. Das erworbene Know-how und entwickelte Framework stellen einen echten Mehrwert dar und diese Projektergebnisse konnten bereits in Kundenprojekten weitergenutzt werden. Insbesondere von dem Ausbau des Simulators und dem geschaffenen Framework für die webbasierte LVS-App konnte bereits profitiert werden.

„Aus unserer Sicht war die Beteiligung am Projekt ein voller Erfolg. Durch den technologischen Fortschritt können wir im Rahmen der Logistik-Suite zukünftig die neuen Features potenziellen Neukunden präsentieren und erhöhen so das Marktpotenzial von w3/max“, freut sich Udo Salewski, Entwicklungsleiter der w3logistics AG.

Lesen Sie auch …

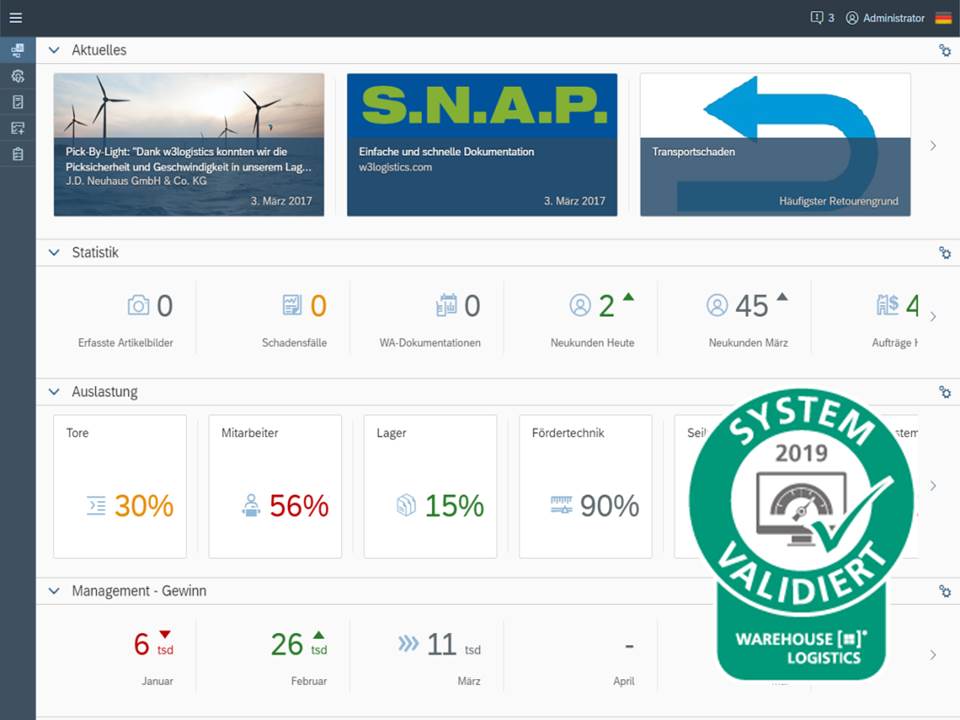

w3/max erfolgreich validiert

Die w3logistics AG hat mit dem Warehouse-Management-System w3/max den Validierungsstempel des Fraunhofer-Instituts für Materialfluss und Logistik (IML) erhalten. Im Juli wurde die w3/max Logistik-Suite in einem umfangreichen Validierungsverfahren durch das Fraunhofer IML validiert. Mit der ... mehr

Packroboter-Anbindung mit w3/max

Die Coldstore Hamm GmbH, die im Jahr 2003 in Betrieb gegangen ist, gilt als Multifunktionslager mit einem 24-Stunden-Service. Das Tiefkühlhaus lagert neben Rotfleisch, Fleischprodukten und Schlachtnebenprodukten für Dritte auch Eis und Backwaren ein. Durch eine moderne Verschieberegalanlage ... mehr

Gefahrstofflagerung mit w3logistics

Die MC-Bauchemie Müller GmbH & Co. KG gilt als einer der führenden internationalen Hersteller bauchemischer Produkte und Techniken und ist mit über 2.500 Mitarbeitern in mehr als 40 Ländern tätig. Die Vielseitigkeit des Produktportfolios und die weltweiten Aktivitäten des Unternehmens bringen spezielle ... mehr