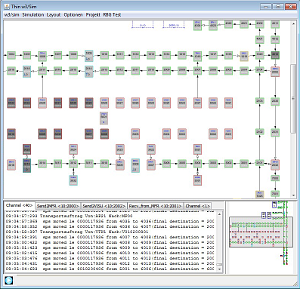

w3/sim – Simulation tool assures quality

The simulation tool w3/sim makes it possible to model and to test all processes of an automated warehouse, starting from materials handling equipment, over material flow system to warehouse management system, without having direct access to the physical conveyor technique.

w3/sim is offered by w3logistics AG as well as a stand-alone product, as also as an integrated part of the warehouse management suite w3/max. Needlessly to say that w3logistcs also uses the tool for its own development of customer projects.

A speciality of w3/sim is the possibility of simulating "foreign" software, thus the end user is not bound to a specific product.

The simulator is an indispensable aid for refactoring projects that require for example a complete exchange of the material flow system:

As a first step, the simulator is configured with the plant layout and the interface logic. Then this system is extensively tested with the old material flow system. This way ensures that the simulator exactly behaves like the existing material flow equipment.

In parallel or afterwards, the development of the new material flow system takes place.

Finally the new MFS can be tested and validated extensively with the simulator even before the actual start of operations. The training of workers can be prepared optimally.

Using the simulator, it was possible to take a new material flow and WMS for a high bay warehouse at KHS GmbH at a single weekend, since the materials handling equipment and the material flow software and the warehouse management software were comprehensively tested beforehand. Deutsches Milchkontor uses w3/sim at its plant in Erfurt after the start of operations as a testing suite for further developments.

Read also …

Warehouse management: Individually or standard

At Stahlwille pickers work with MDEs and data glasses with an individually tailored solution, whereas at BORCHERS Borken two different locations use the same standard despite of different infrastructures. Two solutions – and many satisfied customers of w3logistics ... more

Warehouse optimization: Get more our of your warehouse!

By means of its modular structure, w3/max makes it easy for you to optimize your warehousing processes step by step. This way you can adapt your system to fit changed requirements and your standard WMS becomes an individual solution exactly tailored to your needs. ... more

Material flow: w3logistics controls your equipment

At Corpoplast, the solution of w3logistics operates a small-parts warehouse, and at the Erfurt plant of DMK Deutsches Milchkontor it controls a high bay warehouse with extensive materials handling equipment. All transports are controlled at PLC level and are optimized for manual handling ... more

Industry solution for cold and chilled stores

You operate a cold or chilled cold store and have special requirements for your warehouse mangement system like Thüringer Kühlhäuser? You want to bill your warehouse services like Coldstore Hamm or das Frische- und Gefrierzentrum Rheine? Our industry solution is optimized to match your demands ... more